72 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

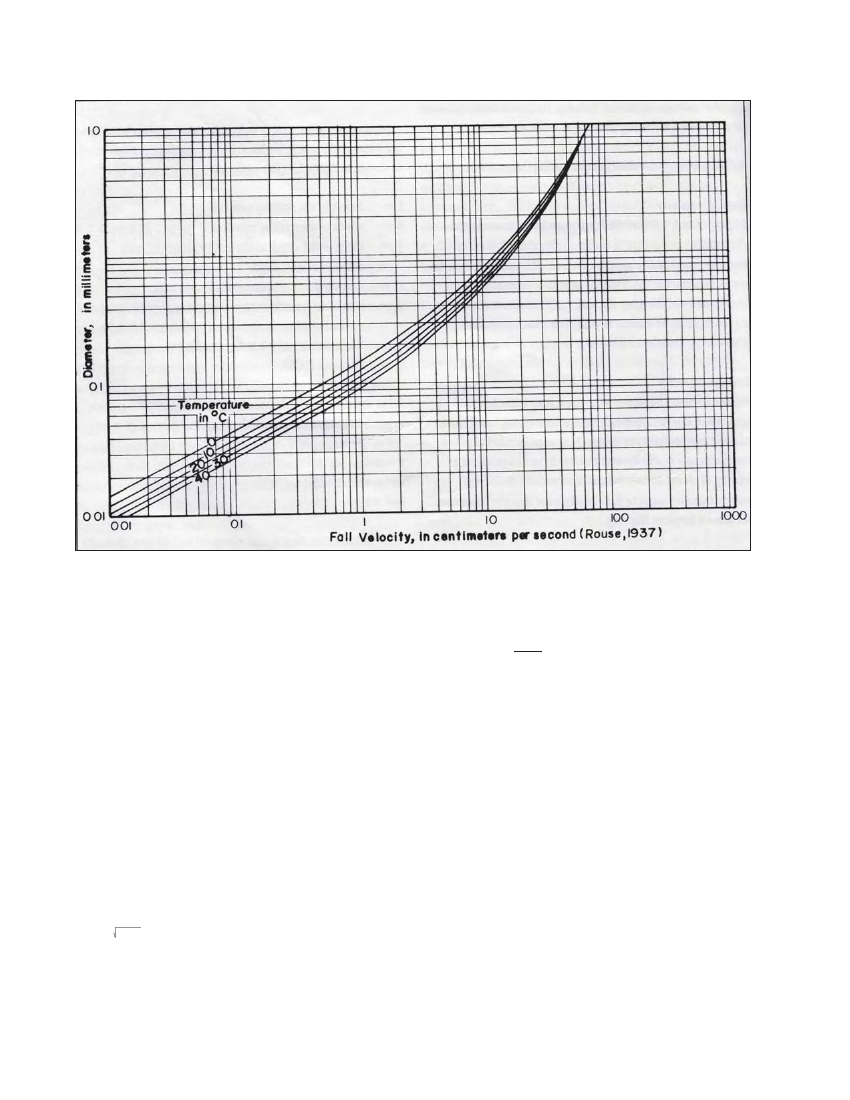

Figure 5.2 Fall velocity of quartz spheres in water

For example, dlimit = 0.2 mm should be selected in a case

where: h = 50 m, suspended particles are mostly pure quartz

or similar minerals, and a Francis turbine is used.

5.3.4 SETTLING DESIGN

The area required for the settling basin and its plan shape are

calculated as follows:

1. Using the criteria discussed in Section 5.3.3, determine

what the range of the scheme is (i.e., low, medium or high

head) and decide on the corresponding minimum particle

size to be settled, i.e. dlimit .

2. Using Figure 5.2, for the selected dlimit , determine the fall

velocity, w.

3. Calculate the required basin surface area (A) using the

following equation: A = 2Q / W Note that a factor of 2 has

been used to allow for turbulence in the basin.

4. With the basin area calculated above, fix either the length,

L, or the width, B, according to site conditions and calculate

the other dimension such that 4 ≤ L/B ≤ 10.

5. Check that the horizontal velocity (V = Q/By ) is less than

0.44 dlimit , i.e. V < 0.24 m/s

where dlimit = 0.3 mm. If not, increase the cross sectional area

(B or y) to meet this condition.

Alternatively Vetter’s equation which is commonly used in

design of small hydro settling basin in Nepal and gives

reasonable estimates of the dimensions required is also worth

mentioning here. The basic philosophy in this method is to

calculate settling efficiency for the particle size considered.

The vetter's equation to determine settling efficiency is:

Wη=hesreett,lηin=g 1ef-fei-c[iewnQ*cAyso]f a settling basin (the result is a ratio and

could be converted into a percentage by multiplying by 100)

w=settling velocity of considered particle size, m/s

As=surface area of the settling basin settling zone, m2

Q=design flow, m3/s

A 90% settling efficiency for particle size based on head as

discussed earlier would be appropriate when using Vetter’s

equation to size settling basin in micro hydro schemes. The

desired efficiency of the settling basin is achieved by finding

the surface area of the settling zone and then dimensioning

the area considering the criteria mentioned in previous

method.

A schematic diagram of a typical settling basin is shown in

Figure 5.1. Double chamber will not be required for small

flows but this arrangement will enhance the settling efficiency

and another advantage is that while sediments are being

flushed in one chamber, the other could continue conveying

flows downstream and thus half of the possible power output

can be generated instead of complete plant shutdown.

5.3.5 STORAGE DESIGN

The concentration of suspended particles in the flow can be

expressed as follows: